Connection & Commissioning#

Chapter goal

Goal: Make the sensor visible in the CMTK and obtain first measurement values.

Prerequisite

The CMTK must be set up according to its own manual (network, access, basic function). These steps are not part of this guide.

1. Mount and connect the sensor#

Mount the sensor rigidly and aligned exactly towards the target to be measured. Even slight angle changes (e.g. holding the sensor in your hand) lead to fluctuating values.

Connect the sensor via a suitable M12-to-M8 cable to an IO-Link port of the CMTK. If the CMTK is powered, at least one green LED should light or blink (sensor ready / IO-Link connection). The second LED can be off or yellow – both are fine.

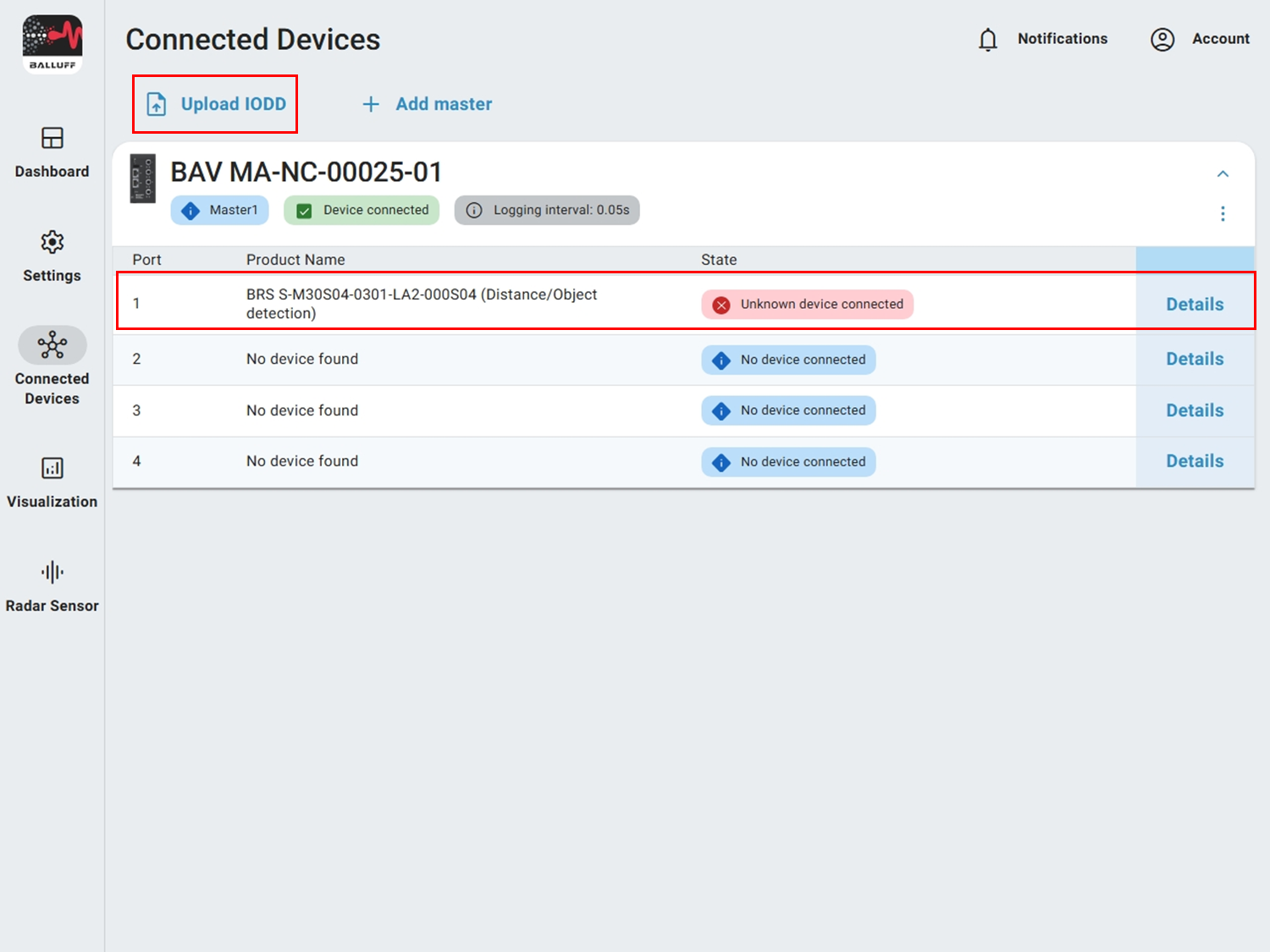

2. Upload IODD#

If the sensor appears with status Unknown device connected, the CMTK does not yet know the IODD. Download the correct IODD from the Balluff Update Platform. For the standard mode you need the variant BRS S-M30 (Distance/Object detection). Import it via the Upload IODD button.

Tip

Unzip the ZIP file before uploading.

3. Reset sensor to factory settings#

Set the sensor to factory settings to obtain a defined starting point.

Warning

All sensor settings are reset and lost irreversibly.

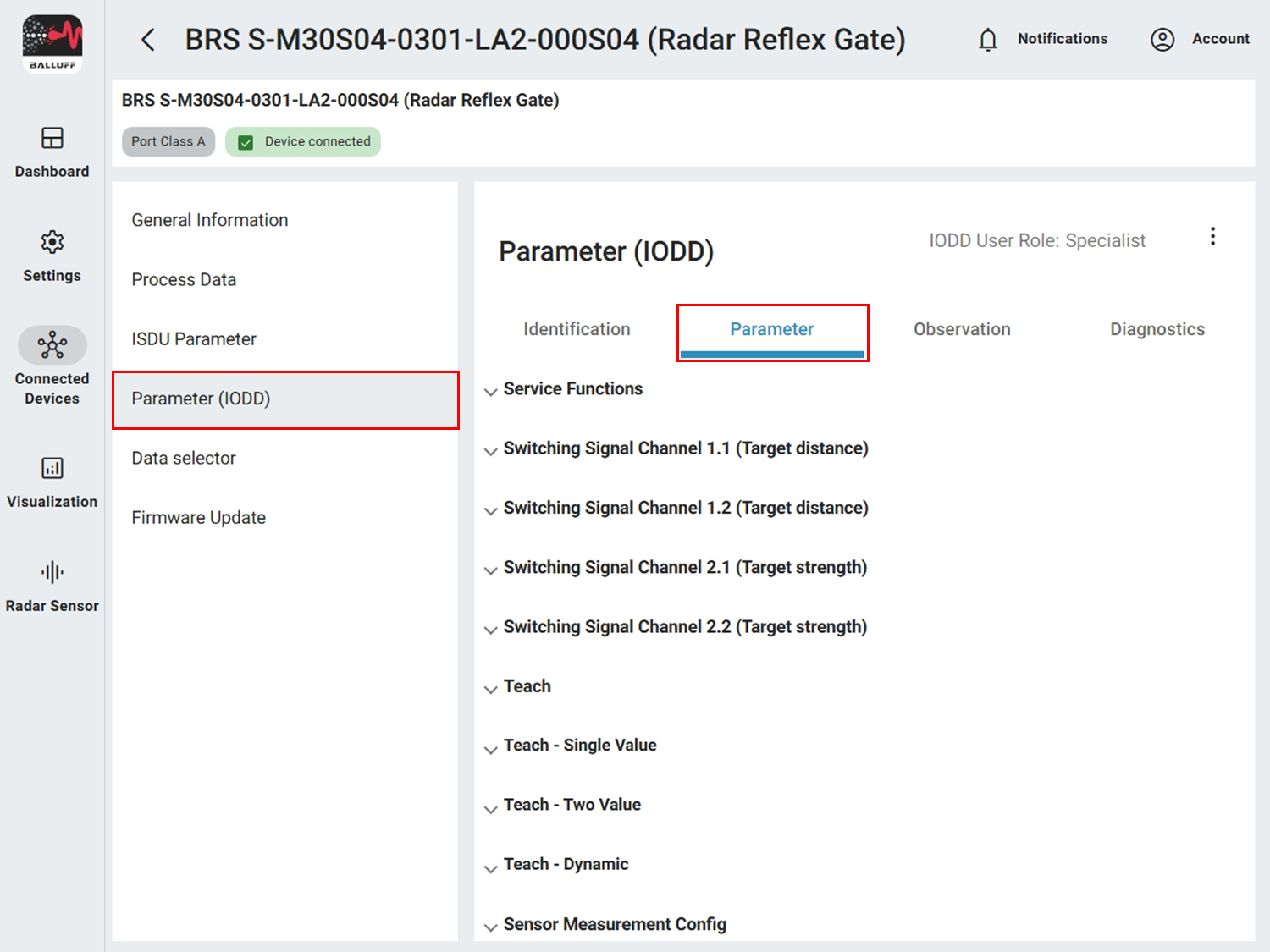

You can find parameters in the CMTK under Parameters (IODD) → Parameters. Select the sensor under Connected devices first.

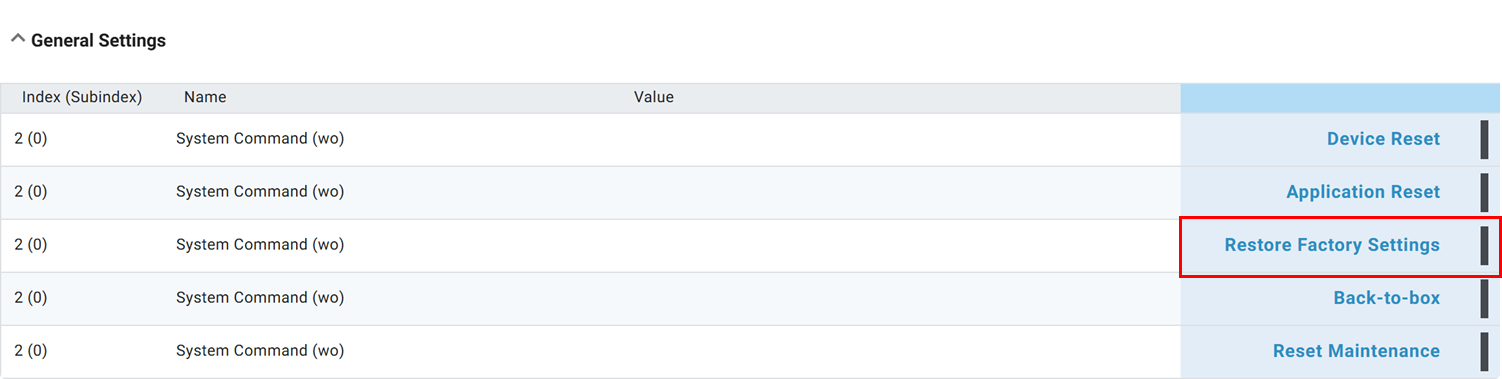

Click General Settings → Restore Factory Settings.

4. Interpret process data#

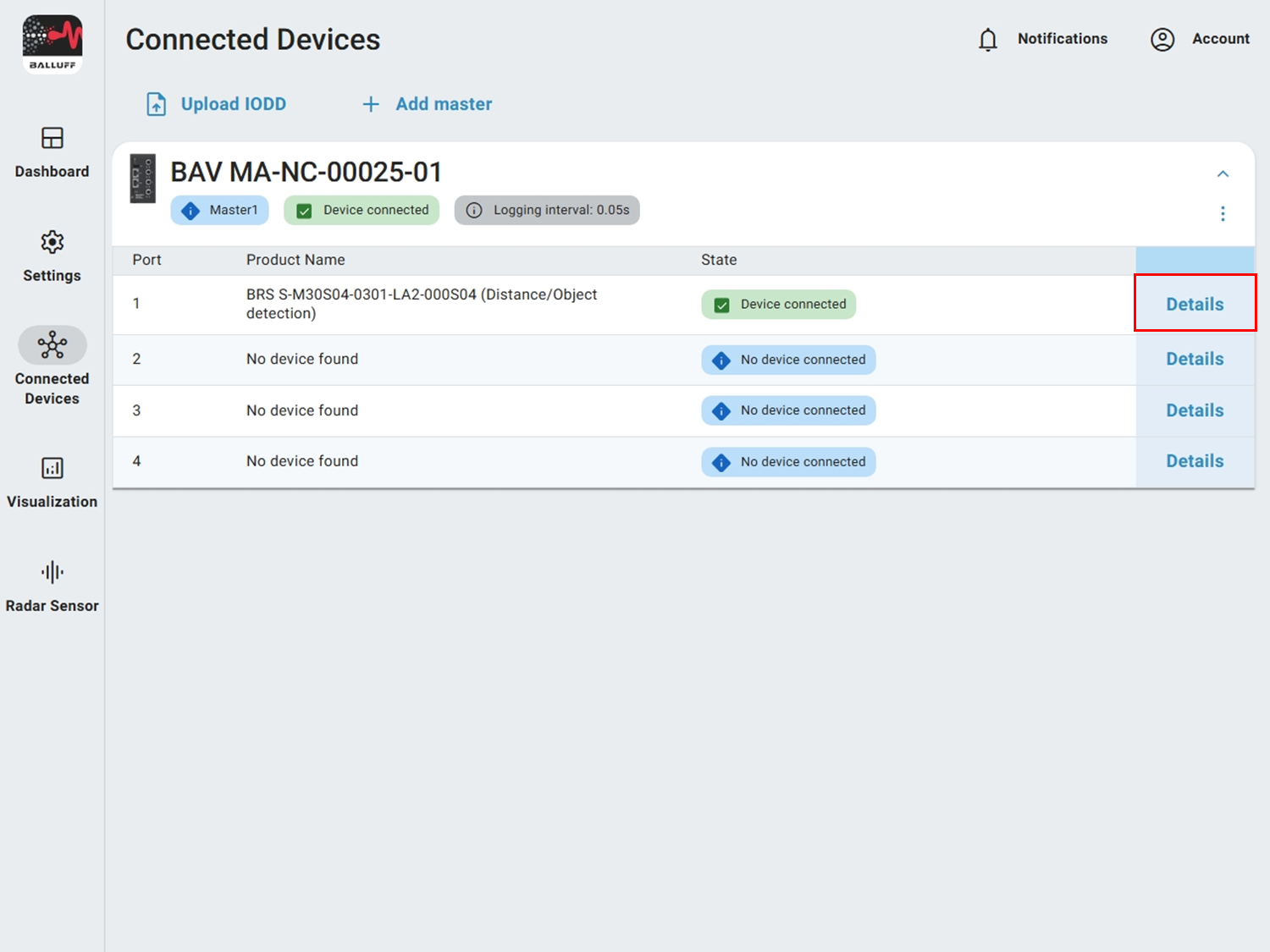

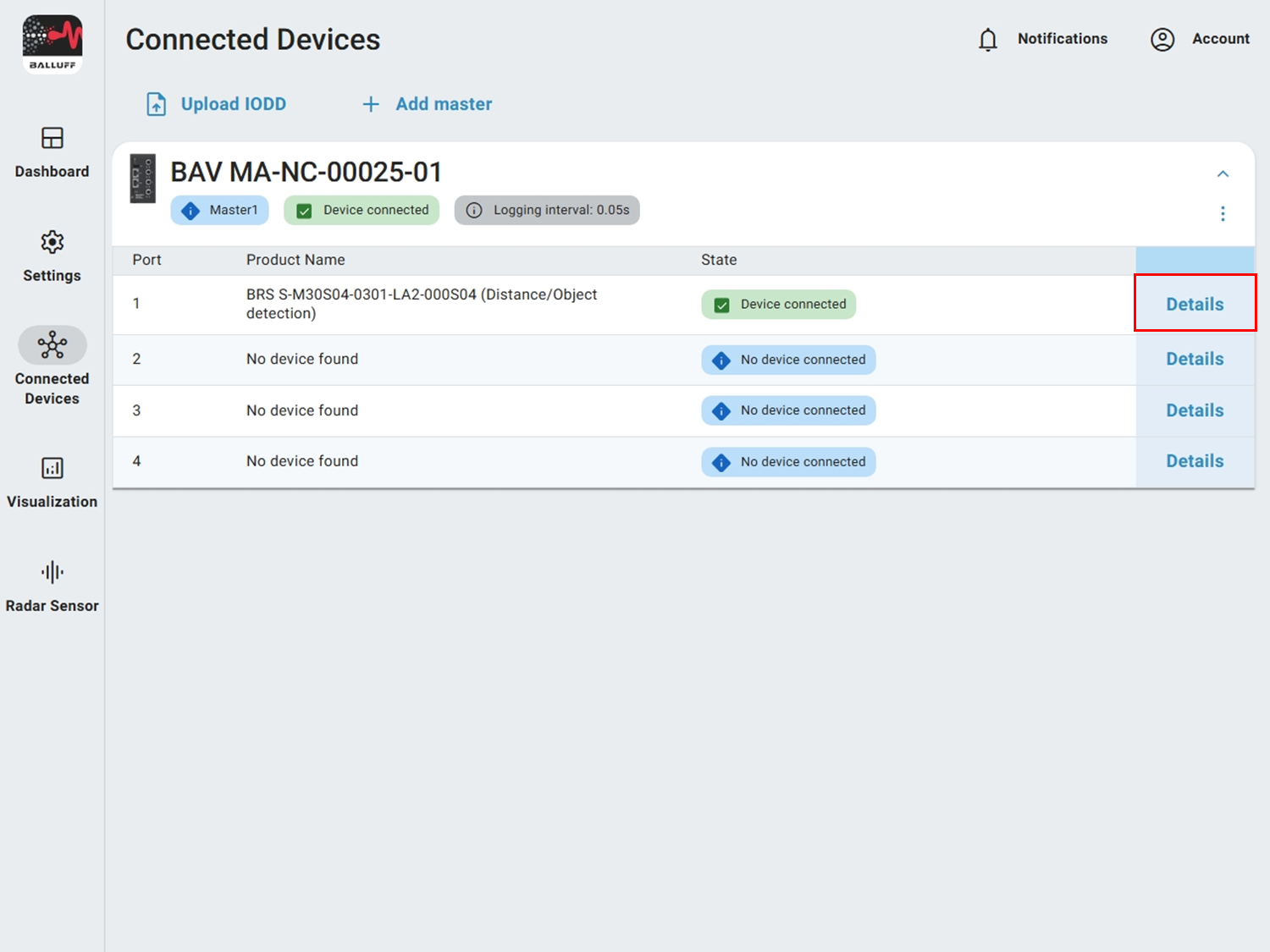

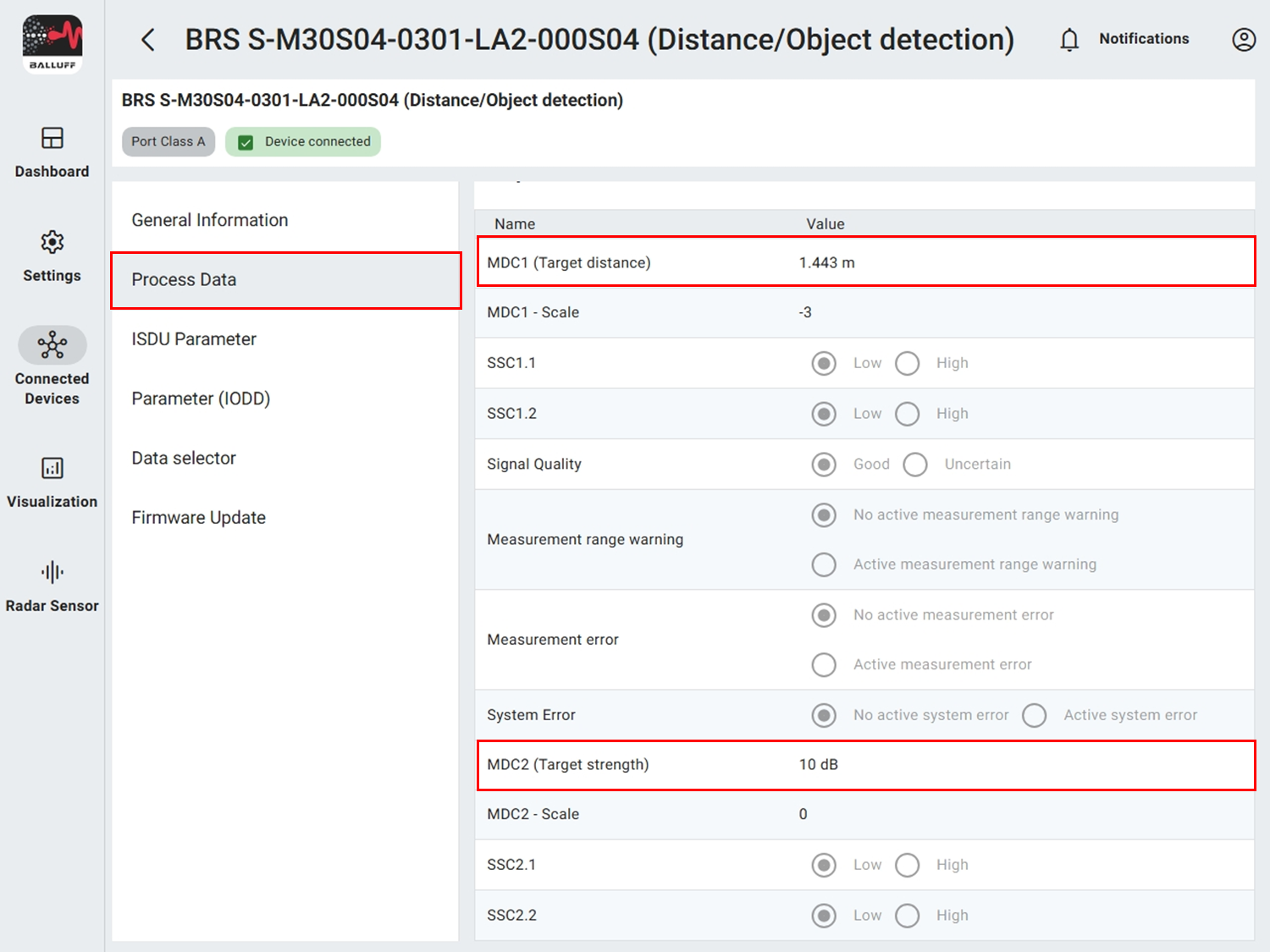

The current process data of the sensor is shown in the process data view under Details.

For a start, the values MDC1 (Target distance) and MDC1 (Target strength) are especially relevant.

MDC1 (Target distance) – Distance#

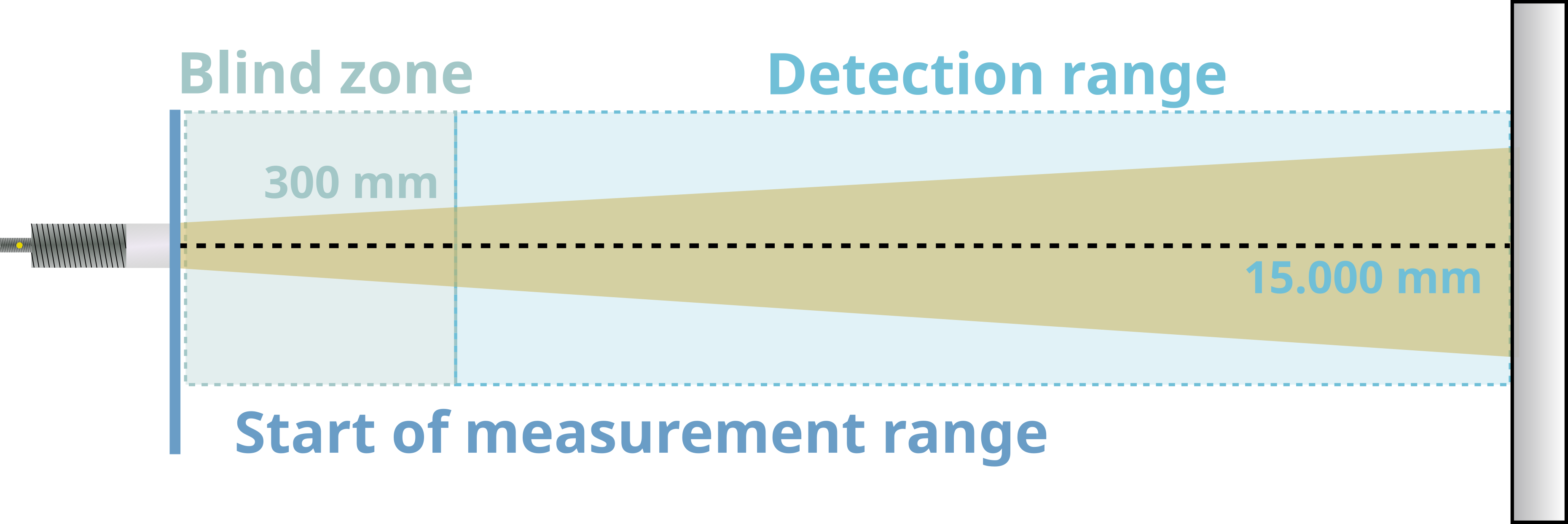

Distance is the measured range (in meters) to the currently selected target. The usable measurement range extends up to 15 m. Below approx. 300 mm the blind zone begins; accuracy drops significantly there. From factory the sensor reports objects from about 150 mm; however measurement error can exceed ±10 mm there. For reliable results the target should be outside the blind zone.

Detection range and blind zone

My distance value is wrong

Tips for optimization are in the next chapter.

MDC1 (Target strength) – Magnitude#

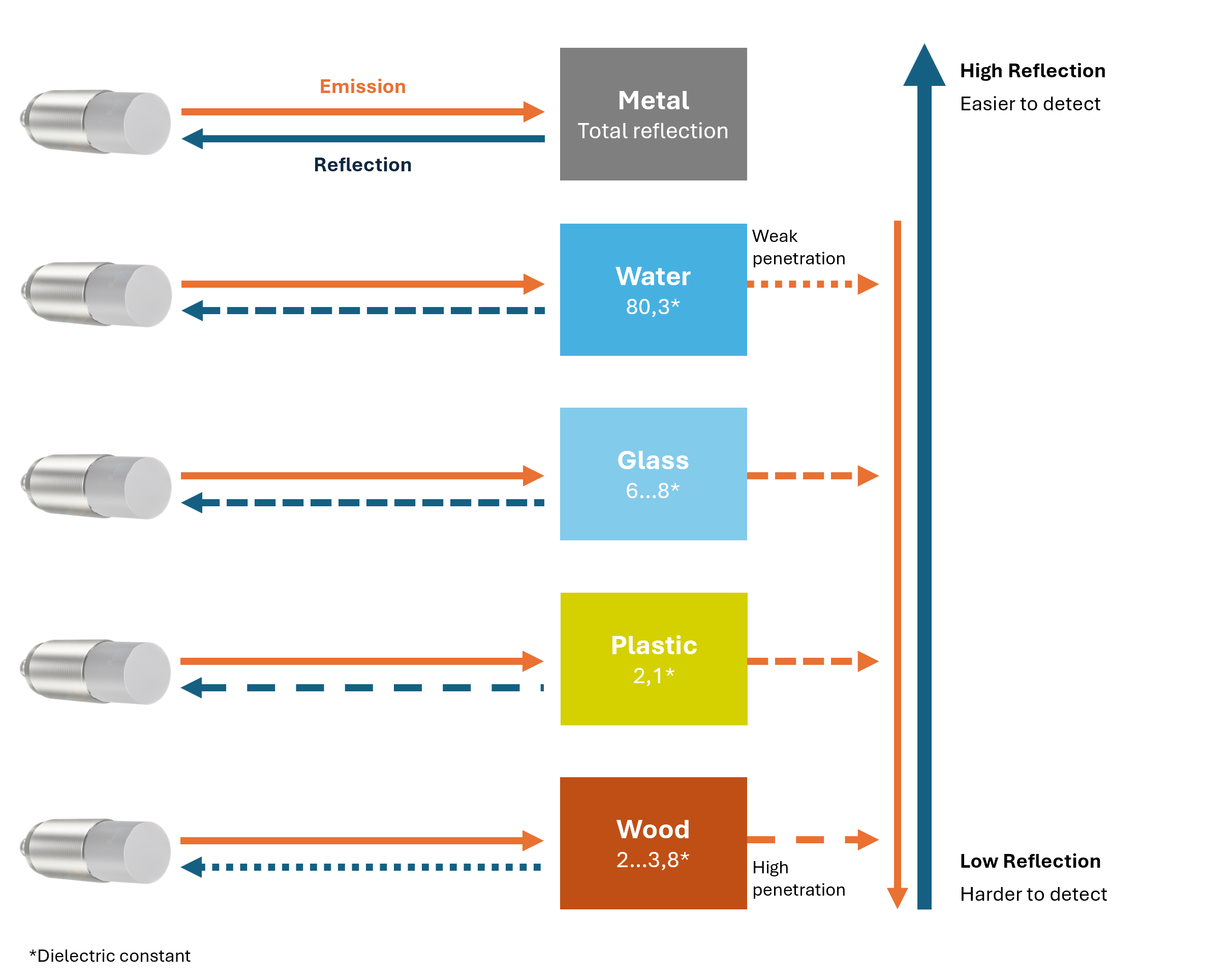

Magnitude describes reflection strength at the computed distance. Different materials and surfaces (metal, plastic, angle, curvature) reflect differently. Matte or angled surfaces often yield lower values. The mounting angle has strong influence. Therefore a clean mounting and alignment are crucial. Align the sensor so magnitude is as high as possible.

Reflectivity of materials

More information on reflectivity is in the Excursus – How does a radar sensor work and the Manual.

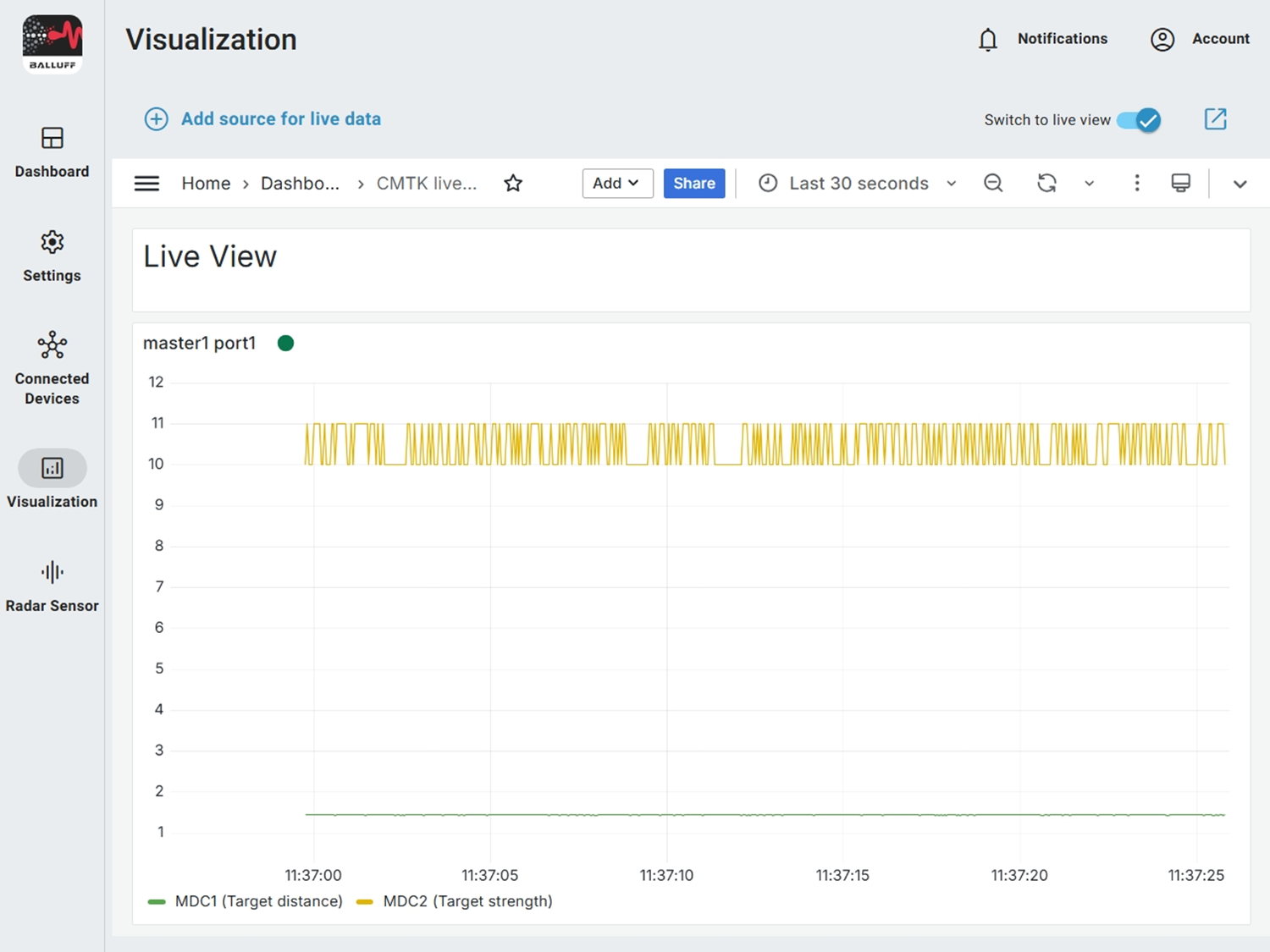

5. Visualize process data#

With the CMTK you can visualize the course of process data – recorded values and live data. This helps especially during alignment.

Tip

Details on visualization are in the CMTK Manual.

- Next section

Step 2 – Distance measurement – Understand & Optimize